How should Ipurchase chicken farming machinery? The main chicken raising equipment is incubator and hatcher.

Chicken coops need to be mechanized for epidemic prevention and sanitation. It is used for washing and disinfecting machinery and facilities of chicken coops, medicine injectors, etc.; for chickens suffering from infectious diseases and deaths of diseases, facilities for incineration are required. Mechanization of feed processing and chicken raising equipment. Conventional feed processing machinery and equipment include raw material warehouses, batching warehouses, finished product warehouses, cleaning equipment, conveying equipment, dust removal systems, metering devices, shredders, mixers, packaging machines, and special bulk feed transport vehicles.

Egg grading, storage and other mechanical facilities; as well as by-product processing and processing. Egg processing and packaging; chicken slaughter, segmentation, packaging and mechanical equipment such as animal protein processing and chicken manure drying treatment. Mechanization of chicken breeding equipment. Including feeding and feeding machinery, water supply system and drinking fountain, chicken cage cleaning, egg collection machinery, etc.

Mechanization of transportation and breeding equipment. Including the transportation of eggs, chicks, adult chickens and broilers. Eggs and chicks travel between the hatchery, the chicken farm, or the machinery between the chicken farm and the egg processing factory. How many mechanized equipment is included in the chicken farming machinery should be vehicles with altered tuning.

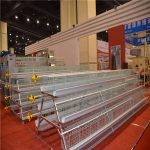

Many chicken farmers have an imbalance between the brooding, rearing and layer houses, which do not meet the requirements. The rearing area is often too small, the rearing density is too large, and the feed and drinking troughs are not enough. It can be said that this is a common problem common to chicken farmers and one of the important factors that affect the economic benefits of laying hens. The quality of chicken raising machinery is not good and not matching. The machinery for raising chicks, growing chickens and laying hens has specifications and ratio requirements. Each machine should be able to match, so as to facilitate the normal growth and development of the chicken group and a reasonable turnover, give full play to the utilization rate and operation rate of the machine, and make the depreciation cost allocated to each hen or per kilogram of eggs more reasonable, thereby Can reduce production costs.

There are also chicken farmers who raise more chickens, use fewer houses or have no extra houses for chickens, and cage the chicks too early, which is unfavorable for the growth and development of the young, and ultimately affects the laying performance of the hens. . Nowadays, laying hens are mostly raised in cages, and chicken cages are indispensable mechanical equipment, and chicken farmers generally pay more attention to it. However, they lack the ability to discern the quality of chicken coops, and tend to be low-priced when buying. The cage is the place where the hens live, produce and sleep. The quality of the chickens cannot be ignored. The quality of the bottom of the cage, the width and the slope of the cage are especially important when buying chicken machinery.