For the selection ofcost-effective poultry farming equipment in India, the first step is to select the appropriate poultry equipment manufacturer according to the poultry farming equipment needed.

The choice of chicken farming equipment and the way of cages are directly related to the economic benefits of farmers. Many farmers have chosen to adopt the method of “multiple chickens and fewer chicken houses”, resulting in a complete imbalance in the proportion of chickens and chicken houses. The feeding area is too small, the stocking density is too large, and the feed and drinking water tanks are not enough. This is one of the important factors affecting the economic benefits of farmers.

Some chicken farmers have more chickens, less housing or no extra housing for chickens. Prematurely feeding the chicks to the cages is not good for the growth and development of the young birds, which ultimately affects the laying performance of the hens. The laying hens are harvested after the hens are opened.

Chicken farming equipment is of low quality and does not match. There are specifications and proportions for equipment for raising chicks, broiler chickens and laying hens. The equipment should be matched to facilitate the normal growth and development of the flock and reasonable turnover, and give full play to the utilization rate and operation rate of the equipment. The depreciation charge allocated to each hen or per kilogram of eggs is more reasonable, thereby reducing production costs.

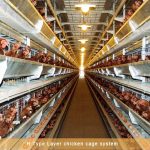

Nowadays, the laying hens are mostly caged, and thebattery layer chicken cagesare indispensable equipment. The chicken farmers generally pay more attention to them. However, the lack of identification of the quality of the chicken cage tends to be low-priced when purchased. Cage is the place where hens live, produce and sleep. The quality of the cage should not be neglected. The quality of the cage bottom, the width and slope of the cage are especially important. The author once witnessed the difference in the quality of chicken cages from two manufacturers in the same chicken farm, resulting in significant differences in egg production, number of dead hunters and egg breaking rates. Another notable and more common problem is not to pack chickens in cages.

When the survival rate of brooding is high, the number of surviving hens exceeds the number of budget tranches, or the hens who are underweight are reluctant to retire. In this case, they are often over-loaded. According to statistics, when the number of cages per cage increased to 5, 22.5% of hens died before 305 days of age. According to the statistics of the production reports accumulated by the author for many years, the flocking rate exceeds the prescribed standard, and the egg production rate is 5% to 15% lower than that of the normal flock.